Short Verdict

SolidWorks and Inventor are two of the most widely used 3D CAD software in the market today. Both programs offer a suite of tools for creating and designing 3D models, assemblies, and simulations for use in engineering and product design.

SolidWorks has a reputation for its intuitive user interface and user-friendly tools. It is known for being easy to learn, making it ideal for beginners and those new to CAD software. The software also has a wide range of simulation and analysis features, which enable users to perform detailed testing and optimization of designs before prototyping. SolidWorks is also recognized for its excellent assembly capabilities, including its mate system and the ability to perform interference detection.

Inventor, on the other hand, is known for its robust parametric modeling capabilities, making it ideal for designing complex mechanical designs. The software also has advanced assembly tools, which enable users to create and edit assemblies with ease. Inventor is particularly useful when working with sheet metal, and it has an excellent frame generator that is ideal for designing metal-based products.

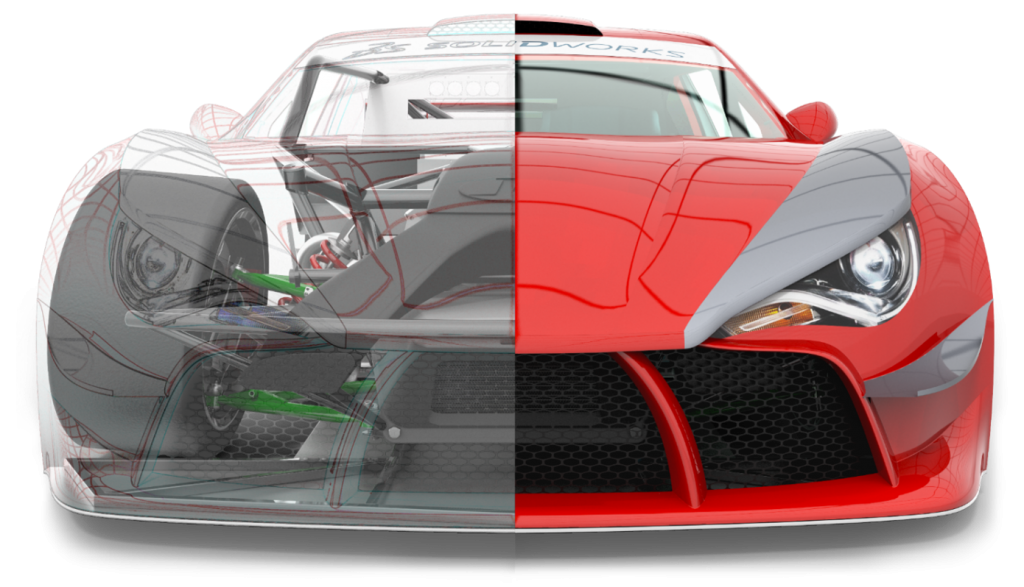

What is SolidWorks?

SolidWorks is 3D computer-aided design (CAD) software developed by Dassault System. It’s used by engineers and designers to create 3D models, assemblies, and technical drawings for a variety of industries such as mechanical engineering, product design, and architecture. SolidWorks offers a user-friendly interface and intuitive design tools that enable users to quickly create and modify designs. It has a wide range of features such as 3D modeling, assembly management, and simulation tools that allow designers to simulate real-world conditions and test designs before creating physical prototypes.

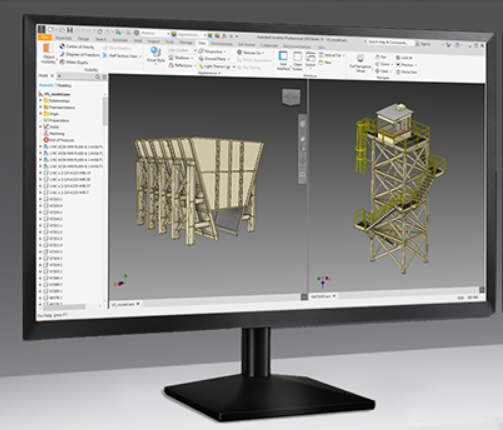

What is Inventor?

Inventor is a professional-grade 3D modeling software program designed for product designers, engineers, and manufacturers. It is a powerful tool that offers advanced features such as parametric modeling, assembly design, sheet metal design, and simulation. Inventor allows users to create complex 3D models and assemblies with thousands of parts. It is ideal for large businesses that require robust features for designing and manufacturing products Inventor is a professional-grade 3D modeling software program designed for professionals.

Advantages and Disadvantages of SolidWorks and Inventor

Advantages of SolidWorks

- User-friendly interface and intuitive design tools: SolidWorks is known for its easy-to-use interface, which makes it accessible to both new and experienced users. Its design tools are also user-friendly, enabling users to create and modify designs with ease.

- Wide range of simulation and analysis tools: SolidWorks offers a wide range of simulation and analysis tools that allow users to test and optimize designs before creating physical prototypes. These tools can help identify and correct design flaws, saving time and money in the prototyping phase.

- Excellent assembly capabilities: SolidWorks has a robust mate system and interference detection, making it easy to manage and edit assemblies. This makes it ideal for product design and engineering applications.

- High performance and stability: SolidWorks is known for its speed and stability, making it suitable for handling large assemblies and complex designs.

- Compatible with a wide range of file formats: SolidWorks supports a variety of file formats, making it easy to collaborate with other CAD software programs.

Disadvantages of SolidWorks

- Expensive: SolidWorks can be expensive, especially for smaller businesses or individuals.

- Limited parametric modeling capabilities: SolidWorks is not as robust as other CAD software when it comes to parametric modeling capabilities.

- May not be suitable for designing certain types of products or structures: SolidWorks is primarily designed for product design and engineering applications, and may not be ideal for designing certain types of structures, such as buildings or bridges.

Advantages of Inventor

- Robust parametric modeling capabilities: Inventor is known for its advanced parametric modeling capabilities, making it ideal for designing complex mechanical designs.

- Advanced assembly tools: Inventor has advanced assembly tools that enable users to create and edit assemblies with ease.

- Excellent sheet metal and frame generator tools: Inventor has robust sheet metal and frame generator tools, making it ideal for designing metal-based products.

- Stable and reliable software: Inventor is known for its stability and reliability, making it suitable for large-scale manufacturing and engineering environments.

- Compatible with a wide range of file formats: Inventor supports a variety of file formats, making it easy to collaborate with other CAD software programs.

Disadvantages of Inventor

- Steeper learning curve: Inventor can have a steeper learning curve compared to other CAD software, which can make it more challenging for beginners or those new to CAD software.

- Limited simulation and analysis tools: Inventor may not have as many simulation and analysis tools as other CAD software.

- Limited compatibility with other software programs: Inventor may have limited compatibility with other software programs outside of the Autodesk ecosystem.

How do both these Programs Work?

SolidWorks

SolidWorks is developed by Dassault System and is one of the most popular CAD software programs in the world. It’s primarily used for mechanical and industrial design, but can also be used for architectural and electrical design.

One of the key features of SolidWorks is its parametric design capabilities. Parametric design is a design approach that enables users to create and modify designs by defining and changing the parameters that define the geometry of the model. This makes it easy to make changes to a design without having to redo the entire model.

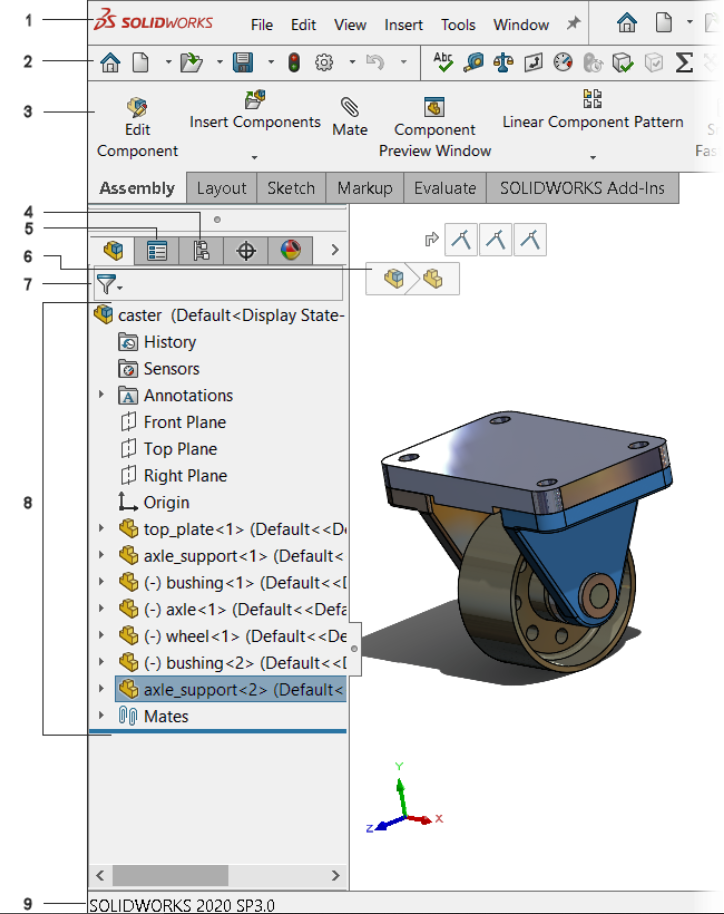

In SolidWorks, users begin by creating a sketch on a 2D plane, which serves as the foundation of the 3D model. The sketch can be created using a variety of tools, including lines, arcs, circles, and rectangles. Once the sketch is complete, it can be extruded or revolved to create a 3D model.

SolidWorks also has a wide range of features for creating and editing assemblies. Users can add and remove parts from the assembly, and specify the relationships between them. The mating system in SolidWorks makes it easy to align and connect different parts of an assembly.

One of the strengths of SolidWorks is its simulation and analysis tools. SolidWorks has a wide range of simulation tools that enable users to test the performance of a design under different conditions. This can help identify potential design flaws and improve the overall quality of the product.

SolidWorks also has a range of add-ins and extensions that enable users to customize the software to meet their specific needs. Additionally, it supports a variety of file formats, making it easy to collaborate with other CAD software programs.

Inventor

Inventor is developed by Autodesk and is primarily used for mechanical design and engineering. It’s known for its advanced parametric modeling capabilities, making it ideal for designing complex mechanical designs.

Inventor works by using sketches to create 3D models. Users can create sketches on a 2D plane, similar to SolidWorks, and then extrude or revolve the sketch to create a 3D model. However, Inventor has more advanced parametric modeling capabilities than SolidWorks, making it possible to create more complex designs.

The inventor also has advanced assembly tools, making it easy to manage and edit assemblies. Users can add and remove parts from an assembly, and specify the relationships between them. The inventor also has robust sheet metal and frame generator tools, making it ideal for designing metal-based products.

The inventor also has a range of simulation and analysis tools that enable users to test the performance of a design under different conditions. While Inventor may not have as many simulation tools as SolidWorks, it’s still a powerful tool for testing and optimizing designs.

One of the strengths of Inventor is its compatibility with other Autodesk software programs, such as AutoCAD and 3ds Max. This makes it easy to integrate Inventor into a larger design workflow.

Comparing the Features of SolidWorks and Inventor

Price

SolidWorks and Inventor offer different pricing plans depending on the needs of the user. SolidWorks offers three different pricing tiers – Standard, Professional, and Premium – with varying levels of functionality and features. Inventor, on the other hand, has a single subscription-based pricing model. Crunching numbers is necessary to determine which software is more cost-effective for your specific needs, but in general, the pricing models of SolidWorks and Inventor are comparable. Therefore, it’s a tie in this category.

UI (User Interface)

The user interface of SolidWorks and Inventor are quite similar, and users familiar with one software can easily transition to the other without a significant learning curve. Both software provides an easy-to-use, intuitive interface, making it a tie in this category.

Compatibility

SolidWorks is not compatible with other software outside of the SolidWorks suite. Inventor, on the other hand, is compatible with other software within the Autodesk family. Compatibility may be an important factor to consider if you use other software in your workflow, so Inventor wins in this category.

Rendering

Both SolidWorks and Inventor have rendering capabilities, but the best renderings often require additional plugins or add-ons. Additional research may be necessary to determine which software is best for your specific rendering needs. Therefore, it’s a tie in this category.

Materials

Both SolidWorks and Inventor have comprehensive material libraries for designing and testing. Neither software has a significant advantage over the other in this category, so it’s a tie.

Simulation

SolidWorks and Inventor both have simulation capabilities for testing designs and structures. Neither software as a significant advantage over the other in this category, so it’s a tie.

Assemblies

Both SolidWorks and Inventor have robust assembly features for creating complex designs. Neither software has a significant advantage over the other in this category, so it’s a tie.

Learning Curve

SolidWorks has a more “viral” presence and may be more easily learned from online tutorials and resources. However, taking a formal class or training may be more effective for learning the software. The inventor has a similar learning curve to SolidWorks and may also benefit from formal training. Thus, there is a tie in this category.

File Format

SolidWorks has its file format (.sldprt and .sldasm) which can be read by other software with a plugin. Inventor, on the other hand, has a proprietary file format (.ipt and .iam) which can be read by other Autodesk software. This may be an important consideration if you need to share files with other software or colleagues who use different software. Inventor wins in this category due to its compatibility with other Autodesk software.

Add-ons and Plugin

SolidWorks and Inventor both have a large selection of add-ons and plug-ins available to extend their functionality. Both software has active user communities that create and share add-ons, making it easy to find and use the plugin. Thus, there is a tie in this category.

Winner

It’s difficult to declare a clear winner between SolidWorks and Inventor as both software have similar capabilities and features. However, if compatibility with other software is an important consideration, then Inventor is the winner due to its compatibility with other Autodesk software. Additionally, if you need to share files with other software or colleagues who use different software, Inventor’s proprietary file format may be advantageous. Ultimately, the choice between SolidWorks and Inventor depends on the specific needs and preferences of the user. It’s recommended to evaluate both software carefully and determine which one is the best fit for your needs.

Conclusion

In conclusion, both SolidWorks and Inventor are popular 3D CAD software that has similar features and capabilities. Both have user-friendly interfaces, robust assembly tools, and comprehensive material libraries. They also have similar simulation and rendering capabilities, as well as active user communities that create and share add-ons and plug-ins when it comes to pricing, the two software have comparable pricing models, making it a tie. However, Inventor has an advantage when it comes to compatibility with other software within the Autodesk family, which can be important for those working in a larger workflow. Inventor’s proprietary file format may also be an advantage when sharing files with other software or colleagues. Overall, the choice between Solidworks and Inventor ultimately depends on the specific needs and preferences of the user. It’s recommended to evaluate both software carefully and determine which one is the best fit for your needs. Both are powerful tools for 3D design and modeling, and whichever one you choose, you will be getting quality software that can meet your design needs.

Summary

SolidWorks and Inventor are two popular 3D CAD software that has similar features and capabilities. Both have a user-friendly interface, robust assembly tools, and comprehensive material libraries. They also have similar simulation and rendering capabilities, as well as active user communities that create and share add-ons and plugins. When it comes to pricing, both software has comparable pricing models, making it a tie. However, Inventor has an advantage when it comes to compatibility with other software within the Autodesk family.

3 comments

Came across this post and your comparison of Solidworks vs Inventor is so inaccurate that I have a really difficult time believing this is a site dedicated to 3D design systems. The idea that Inventor has more parametric modeling capabilities than Solidworks is so patently false it might as well be a Trump speech.

SolidWorks wrote the book on parametric modeling and for Inventor to even be within hailing distance of competitive with Solidwork’s parametric modeling abilities basically requires that you be a programmer. How about this… Inventor has no width mate, symmetric requires you have 2 different components, the 3D sketching is entirely unusable, and there’s about 0 ability to use multi-body parts. Solidworks is literally so far ahead of the game here that you don’t even know where they are.

I can tell from your post that you’ve never used the program for an extended period of time or asked “What can’t Solidworks do?” Because Inventor is an absolute dog of a program and anyone who’s used SW for any period of time knows Solidworks WILL decrease modeling and drawings by 30~50%.

Written by a current Inventor user and CSWP

Your blog’s influence stands as a shining testament to its excellence and the profound insights it generously offers.

Comparing SOLIDWORKS and Inventor in 2023 offers valuable insights for CAD users. Explore this head-to-head comparison to make informed decisions about your design software.