Short Verdict

The short verdict falls to Creo. It provides more advanced features and customization options and is more powerful and flexible than SolidWorks.

What is SolidWorks?

SolidWorks is a robust computer-aided design (CAD) software program introduced in 1995. It is primarily used by aerospace, automotive, manufacturing, and engineering industries to create 3D models of parts and assemblies. With its advanced capabilities, including parametric, assembly, and surface modeling, SolidWorks provides various tools for designing complex 3D models. In addition to modeling, SolidWorks has built-in features that enhance collaboration among team members, making it a preferred choice for remote or distributed teams.

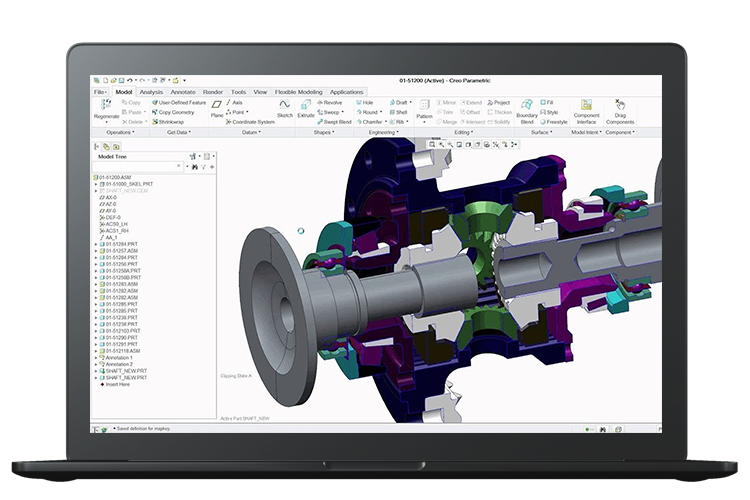

What is Creo?

Creo is a computer-aided design software suite developed by PTC, used for creating, modifying, analyzing, and optimizing product designs in industries such as manufacturing and engineering. It offers modules such as Creo Parametric, Creo Simulate, Creo Direct, Creo Layout, Creo Options Modeler, Creo View, and Creo Illustrate. Creo enables easy collaboration among team members, has a parametric design approach for quick and easy design changes, and provides simulation capabilities for identifying potential design issues before building physical prototypes. Its versatility, and advanced capabilities make it a preferred choice for designers and engineers.

Advantages and Disadvantages of SolidWorks and Creo

Advantages of SolidWorks

- SolidWorks is a powerful CAD software with many tools for creating complex 3D models.

- SolidWorks has an intuitive user interface with easy-to-use tools.

- It offers various modeling capabilities, including parametric, assembly, and surface modeling.

- SolidWorks has a range of collaboration tools, making it an excellent option for teams working on the same project.

- The software also offers simulation and analysis tools for testing and validating designs.

- SolidWorks has a large user community with various online resources available for learning and troubleshooting.

Disadvantages of SolidWorks

- SolidWorks can be expensive for individual users or small businesses.

- It requires high-end hardware specifications to run smoothly.

- The software can be complex and difficult to learn for new users.

- SolidWorks does not support all file formats; some file conversions can result in data loss or accuracy.

- It may require frequent updates and maintenance to keep the software running smoothly.

Advantages of Creo

- Offers a wide range of tools and features for advanced 3D modeling, simulation, and collaboration.

- Has a parametric design approach for easy and quick design changes, reducing design cycle times.

- Provides simulation capabilities for identifying potential design issues before physical prototypes are built, reducing time and cost.

- Offers modules that cater to different design needs, making it a versatile tool for designers and engineers.

- Enables easy collaboration among team members, as well as with suppliers and customers.

Disadvantages of Creo

- Can be complex and difficult to learn, especially for beginners.

- Can be expensive, with pricing varying depending on the modules and licensing options chosen.

- May require powerful hardware to run smoothly, which can add to the overall cost.

How do both these Programs Work?

SolidWorks

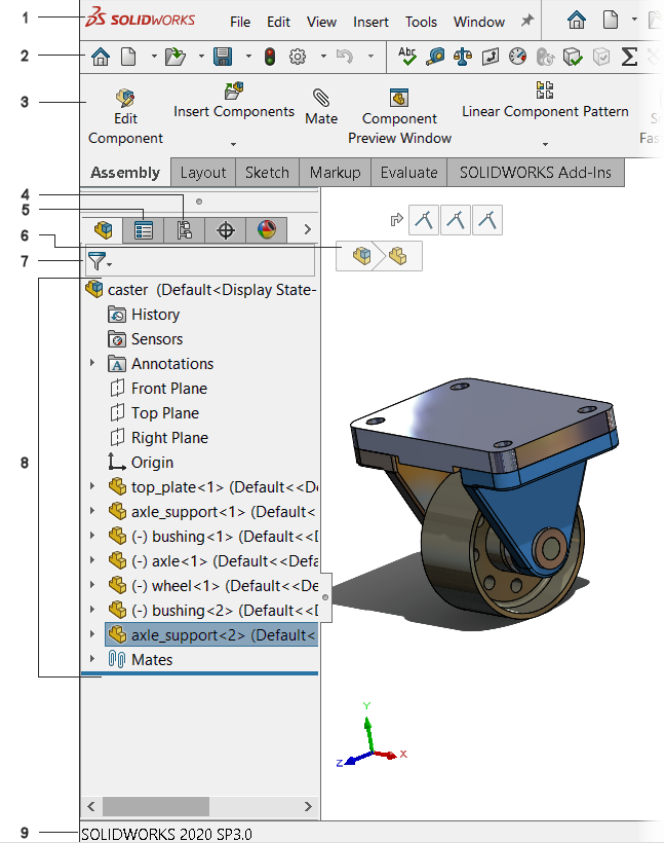

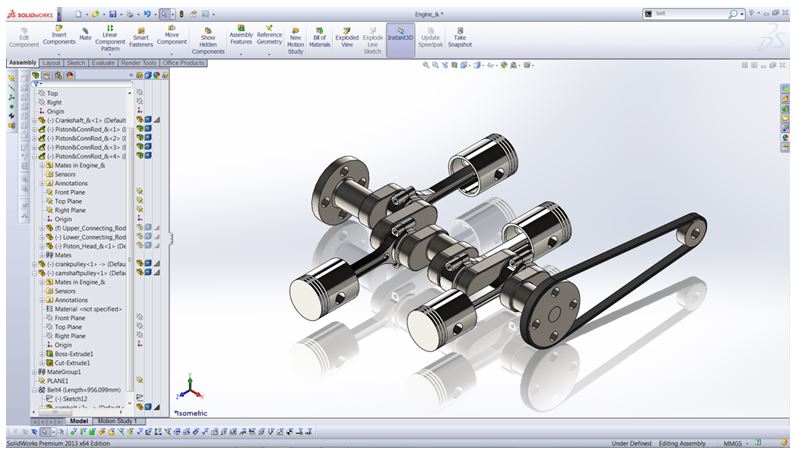

SolidWorks is a feature-rich computer-aided design (CAD) software that excels at handling complex assemblies and creating 3D models. Its feature-based modeling approach enables users to create models by adding and modifying features such as extrudes, revolves, and sweeps. The software also offers advanced surfacing tools for creating complex organic shapes. With its easy handling of large assemblies, SolidWorks is an ideal tool for projects with multiple components. SolidWorks also includes simulation tools for testing designs and ensuring they meet the requirements. These simulation tools test factors such as stress, deformation, and motion to ensure the design is optimized for its intended application. SolidWorks is also compatible with various file formats, including those commonly used in the automotive and aerospace industries.

Creo

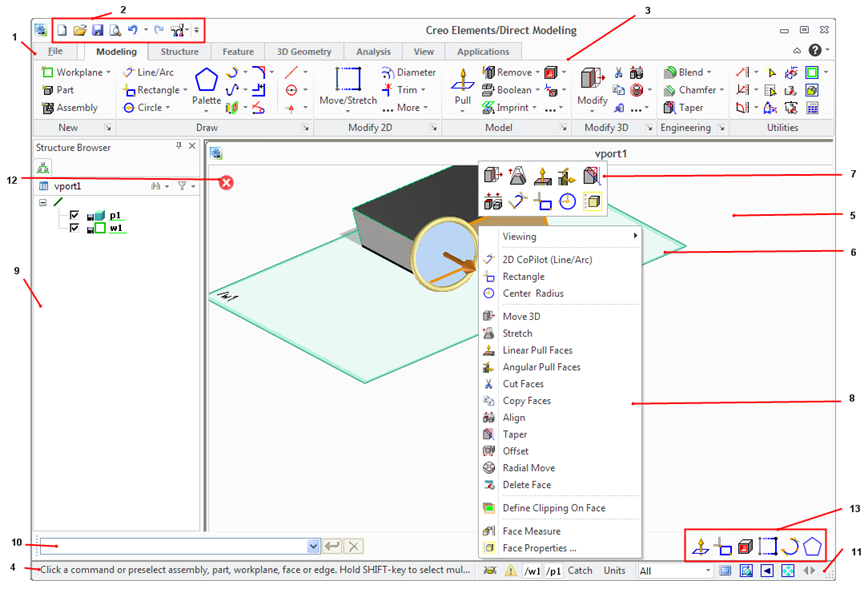

Creo works as a comprehensive computer-aided design (CAD) software suite that provides advanced 3D modeling, simulation, and collaboration capabilities for product designs in industries such as manufacturing and engineering. Creo’s primary module, Creo Parametric, employs a parametric design approach, which allows designers and engineers to create and modify product designs with ease and precision. Creo Parametric stores the design parameters and relationships in a database, making it easy to make changes. Creo also provides simulation capabilities through Creo Simulate, which uses finite element analysis (FEA) to simulate product performance under different conditions. Creo Direct, another module of Creo, provides direct modeling capabilities for fast and flexible design changes. Creo Layout is used for 2D schematic design and layout. Creo Options Modeler enables the creation of complex product configurations and variants. Creo View provides visualization and collaboration capabilities, and Creo Illustrate is used for creating technical illustrations and animations.

Comparing the Features of SolidWorks and Creo

Price

SolidWorks pricing is subscription-based, with monthly or yearly options. It offers a free trial and different versions for students and educators. SolidWorks’ standard version costs around $3,995, while the premium version can cost around $7,995. Creo pricing is based on a perpetual license, with options for purchasing different modules depending on the user’s needs. Creo’s perpetual license is typically more expensive upfront but provides lifetime software access without recurring costs. The cost of Creo can range from around $2,200 to $9,500, depending on the specific modules and licensing options chosen. While SolidWorks may be more affordable upfront, it requires ongoing subscription payments, which can add up over time. Creo’s perpetual license may be more expensive upfront, but it can be more cost-effective in the long run, especially for businesses that plan to use the software for several years.

UI (User Interface)

SolidWorks has a relatively simple and user-friendly UI, which makes it easy for new users to get started quickly. The software’s layout is intuitive and easy to navigate, with clear menus and icons that provide easy access to tools and features. The UI also features customizable toolbars and shortcuts, allowing users to maximize their workspace. On the other hand, Creo has a more complex UI with a steeper learning curve, especially for new users. The software’s layout is more cluttered, and the menu structure can be confusing. However, once users become familiar with the UI, they will find Creo offers more advanced capabilities than SolidWorks. The UI also offers a variety of customization options, allowing users to create their own toolbars and shortcuts for faster access to frequently used tools and features.

Compatibility

SolidWorks is primarily designed to work with native SolidWorks files (SLDPRT and SLDASM), but it can also import and export a wide range of file formats, including STEP, IGES, and STL. SolidWorks can also export to neutral file formats like DXF and DWG for use with other CAD software programs. Creo is primarily designed to work with native Creo files (PRT and ASM), but it can also import and export a wide range of file formats, including STEP, IGES, and STL. Creo can also export to neutral file formats like DXF and DWG and import and export SolidWorks files. While both programs can import and export various file formats, their compatibility may be limited. Additionally, features specific to one program may not be recognized or require manual adjustment when imported into another.

Rendering

SolidWorks offers a built-in rendering engine called PhotoView 360, which allows users to create basic renderings of their designs. PhotoView 360 provides a variety of lighting and material options, as well as the ability to adjust camera settings and add decals or textures to the final rendering. However, the quality of the rendering can sometimes appear flat and lacks the ability to create realistic textures, shadows, and reflections. Creo offers a built-in rendering engine called KeyShot, which offers advanced capabilities for creating highly realistic renderings of 3D designs. KeyShot provides a variety of lighting and material options, as well as the ability to add textures, decals, and labels to the final rendering. It offers advanced capabilities for creating realistic shadows, reflections, and transparency effects.

Materials

Both programs have extensive material libraries. SolidWorks offers a range of materials, including metals, plastics, composites, and more. The materials are categorized and can be applied to individual parts or assemblies. Creo offers a range of materials similar to SolidWorks, but the quality of the material representation is generally more realistic. Additionally, Creo offers advanced capabilities for creating custom materials, allowing users to define specific properties such as density, thermal conductivity, and more.

Simulation

Both programs provide comprehensive tools for performing finite element analysis (FEA) and computational fluid dynamics (CFD) simulations. SolidWorks offers an integrated simulation tool called SolidWorks Simulation, which allows users to perform linear and nonlinear analysis, thermal analysis, and more. The software provides a range of material models and boundary conditions and the ability to perform dynamic simulations. However, the complexity of the simulation models is limited, and the quality of the results may not be as accurate as other standalone simulation software programs. Creo offers an integrated simulation tool called Creo Simulation Live, which provides real-time simulation capabilities. Creo Simulation Live allows users to perform simulations while designing the model, providing immediate feedback on the impact of design changes. Also, Creo offers more advanced simulation capabilities through its partnership with ANSYS, a leading simulation software provider, allowing users to perform more complex simulations such as fluid-structure interaction, electromagnetic simulations, and more.

Assemblies

SolidWorks offers a range of assembly features such as mates, patterns, and configurations, allowing users to create and manipulate complex assemblies easily. The software also provides a range of tools for analyzing and testing assemblies, such as motion simulation and interference detection. However, some users have reported issues with the performance of SolidWorks when working with large assemblies, which can impact productivity. Creo offers a similarly advanced assembly design capability, with features such as dynamic assembly motion, exploded views, and interference detection. Creo also offers advanced capabilities for managing assembly variations, allowing users to create and test multiple design options within a single assembly.

Learning Curve

Both programs require some level of training to use effectively. SolidWorks offers an easy-to-use interface and a range of features that make it accessible to users with little or no CAD experience. The software also provides various resources such as tutorials, forums, and webinars, making it easy for users to learn how to use the software effectively. Creo, on the other hand, has a steeper learning curve and may be more difficult for users with little CAD experience. The software offers a range of advanced features and capabilities, but these may be overwhelming for new users. Nevertheless, Creo provides a range of resources, such as tutorials, forums, and user groups, to help users learn the software effectively.

File Format

SolidWorks uses a proprietary file format called SLDASM for assemblies, SLDPR for part files, and SLDDRW for drawings. SolidWorks supports these file formats and can be opened and edited within the software and exported to other formats such as STEP, IGES, and STL. However, compatibility issues can arise when transferring files between SolidWorks and other CAD software programs due to the proprietary nature of the file format. On the other hand, Creo uses a neutral file format called STEP for saving and sharing designs. Other CAD software programs widely support this file format and can be opened and edited within Creo and exported to other file formats such as IGES, STL, and VRML. However, using a neutral file format can result in some loss of design information and features when transferring files between Creo and other CAD software programs.

Add-ons and Plugin

SolidWorks offers a range of add-ons and plugins through the SolidWorks app store. These include tools for simulation, product data management, electrical design, and more. The app store also features plugins developed by third-party developers that offer additional functionality and features for SolidWorks. Creo also offers a range of add-ons and plugins available through the Creo app store. These include tools for simulation, product data management, 3D printing, and more. The app store also features plugins developed by third-party developers that offer additional functionality and features for Creo.

Winner

Creo is the better option for those requiring more advanced features and customization options, as it is generally more powerful and flexible than SolidWorks.

Conclusion

SolidWorks and Creo are two popular CAD software platforms, with various differences such as pricing, user interface, compatibility, rendering, materials, simulation, assemblies, learning curve, file format, and add-ons/plugins. Both programs offer a range of tools and features for designing and simulating complex parts and assemblies. Still, their advantages and disadvantages vary depending on the user’s specific needs and priorities.

Summary

Both SolidWorks and Creo are powerful CAD software platforms that offer a wide range of tools and features for designing and simulating complex parts and assemblies. While the two programs have their own unique advantages and disadvantages, the final decision ultimately depends on the specific needs and priorities of the user. With proper research and consideration, users can make an informed decision that aligns with their specific needs and helps them create high-quality designs efficiently and effectively.