Short Verdict

Siemens NX and SolidWorks are both powerful and widely used CAD software programs, but they have different strengths and weaknesses. Siemens NX is known for its advanced capabilities in manufacturing and engineering, such as CAM and CAE, while SolidWorks is known for its ease of use and versatility in product design.

Ultimately, the choice between Siemens NX and SolidWorks depends on the specific needs and preferences of the user. If you need advanced manufacturing and engineering capabilities, Siemens NX may be the better option, while if you prioritize ease of use and versatility, SolidWorks may be the better choice.

What is Siemens NX?

Siemens NX, also known as Siemens NX or just NX, is a powerful computer-aided design (CAD), computer-aided engineering (CAE), and computer-aided manufacturing (CAM) software program. It is developed by Siemens Digital Industries Software and is used by designers, engineers, and manufacturers to create, simulate, and optimize products and production processes. Siemens NX offers a wide range of tools and features for design, drafting, modeling, simulation, analysis, and manufacturing. It is used in industries such as aerospace, automotive, industrial machinery, and consumer products, among others. Siemens NX is known for its advanced capabilities in manufacturing and engineering, such as product lifecycle management (PLM), computer numerical control (CNC) programming, and finite element analysis (FEA). It is a powerful tool for designing and producing complex products and systems.

What is SolidWorks?

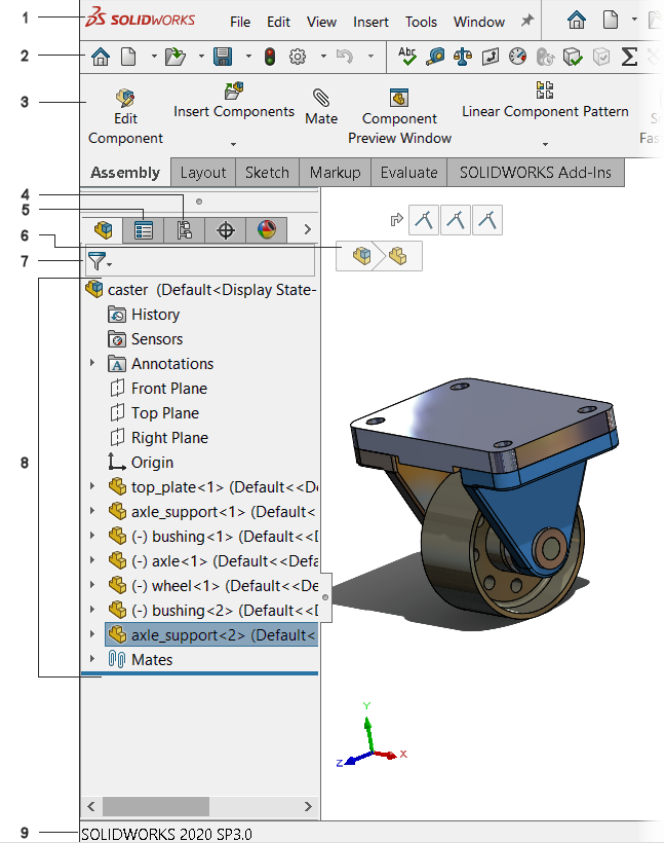

SolidWorks is a powerful 3D CAD software program that is widely used by designers and engineers in a variety of industries. It is developed by Dassault Systems and is known for its ease of use, versatility, and comprehensive tools and features for product design, simulation, and visualization. SolidWorks offers a wide range of tools for 3D modeling, drafting, simulation, analysis, and visualization, including mechanical design, electrical design, and sheet metal design. It is used in industries such as aerospace, automotive, consumer products, and medical devices, among others. SolidWorks is known for its user-friendly interface and intuitive workflow, making it a popular choice for designers and engineers who want to quickly create and iterate on product designs. It is a powerful tool for visualizing and testing product concepts, and for producing high-quality 3D models and technical drawings.

Advantages and Disadvantages of Siemens NX and SolidWorks

Advantages of Siemens NX

- Advanced manufacturing and engineering capabilities, such as CAM and CAE, are particularly useful for complex product designs and production processes

- High level of customization and flexibility, allowing users to tailor the software to their specific needs and workflows

- Strong product lifecycle management (PLM) capabilities, making it a comprehensive solution for managing product development processes from start to finish

- Robust simulation and analysis tools, such as finite element analysis (FEA) and computational fluid dynamics (CFD), allow users to simulate and test product designs under real-world conditions

- Strong community support and user forums, provide access to a wealth of knowledge and resources

Disadvantages of Siemens NX

- The steep learning curve, as the software, is complex and requires a significant investment of time and effort to master

- High cost, as the software is more expensive than many other CAD programs on the market

- Limited third-party support and integration, as the software is less commonly used than some other CAD programs

- Heavy system requirements, as the software requires a powerful computer and graphics card to run smoothly

Advantages of SolidWorks

- User-friendly interface and intuitive workflow, making it easy to learn and use

- Comprehensive tools and features for product design, simulation, and visualization, allowing users to quickly create and iterate on product concepts

- Strong community support and user forums, provide access to a wealth of knowledge and resources

- Good third-party support and integration, with a wide range of plugins and add-ons available for the software

- Good value for money, with affordable pricing and flexible licensing options

Check out our article on AutoCAD Vs SolidWorks

Disadvantages of SolidWorks

- Limited manufacturing and engineering capabilities compared to Siemens NX, which may be a disadvantage for complex product designs and production processes

- Limited customization and flexibility compared to Siemens NX, as the software is more rigid in terms of workflow and functionality

- Limited simulation and analysis capabilities compared to Siemens NX, although it does offer some basic simulation tools

- Limited scalability for larger organizations, as the software is better suited to small and medium-sized businesses.

How do both these Programs Work?

Siemens NX

Siemens NX is a powerful and versatile CAD/CAM/CAE software package that is widely used in a range of industries, including aerospace, automotive, and industrial machinery. Developed by Siemens PLM Software, Siemens NX offers a comprehensive toolset for designing and manufacturing complex parts and assemblies.

One of the key strengths of Siemens NX is its advanced simulation capabilities. The software allows users to analyze the performance of parts and assemblies under different conditions, providing valuable insights into how a product will behave in real-world scenarios. This is particularly important in industries such as aerospace and automotive, where safety and reliability are of the utmost importance.

In addition to its simulation capabilities, Siemens NX also supports a range of manufacturing processes. The software includes tools for additive manufacturing, CNC machining, and sheet metal fabrication, among others. This means that users can design parts and assemblies with specific manufacturing processes in mind, streamlining the production process and reducing costs.

Another notable feature of Siemens NX is its parametric modeling capabilities. This allows users to create parts and assemblies that can be easily modified and updated as requirements change. This is particularly useful in industries where products are subject to frequent updates and revisions.

Overall, Siemens NX is a powerful and flexible CAD/CAM/CAE software package that is well-suited to a range of industries. Its advanced simulation capabilities, support for a range of manufacturing processes, and parametric modeling capabilities make it an essential tool for designing and manufacturing complex products.

SolidWorks

SolidWorks is a widely used 3D CAD software package that is particularly popular in the mechanical engineering industry. Developed by Dassault Systems the software offers a range of tools for creating 3D models of parts and assemblies.

The user-friendly interface of SolidWorks is one of its main advantages. The software is designed to be easy to use, with a range of intuitive tools and features that allow users to quickly and easily create complex 3D models. This makes it a popular choice among mechanical engineers who need to design and model products quickly and efficiently.

In addition to its user-friendly interface, SolidWorks also includes a range of advanced features for creating 3D models. These include parametric modeling, assembly modeling, and drafting tools. This allows users to create parts and assemblies that can be easily modified and updated as requirements change.

Another notable feature of SolidWorks is its simulation and analysis capabilities. The software includes tools for evaluating the performance of parts and assemblies under different conditions, allowing engineers to test their designs before they are manufactured. This helps to ensure that products are safe, reliable, and perform as intended.

Overall, SolidWorks is a powerful and versatile 3D CAD software package that is widely used in the mechanical engineering industry. Its user-friendly interface, range of advanced features, and simulation and analysis capabilities make it an essential tool for designing and modeling complex products.

Comparing the Features of Siemens NX vs SolidWorks

Features

Siemens NX offers a comprehensive toolset for designing and manufacturing complex parts and assemblies. Its advanced simulation capabilities, support for a range of manufacturing processes, and parametric modeling capabilities make it a powerful and versatile software package.

SolidWorks, on the other hand, is focused primarily on 3D CAD modeling. Its user-friendly interface and range of advanced features, including parametric modeling and assembly modeling, make it a popular choice among mechanical engineers.

One area where Siemens NX has a clear advantage over SolidWorks is its simulation capabilities. Siemens NX offers advanced simulation tools for analyzing the performance of parts and assemblies under different conditions, while SolidWorks’ simulation and analysis tools are more limited in scope.

Pricing

The pricing of Siemens NX and SolidWorks can vary depending on several factors, including the specific features and modules that are included. However, in general, Siemens NX is more expensive than SolidWorks.

Siemens NX is typically sold on a subscription basis, with pricing starting at around $7,500 per year for a basic license. Additional modules and features can increase the price significantly.

SolidWorks, on the other hand, is available in a range of different editions, including a free version for personal use. The professional edition of SolidWorks typically starts at around $3,995, with additional modules and features available at extra cost.

One area where SolidWorks has an advantage over Siemens NX in terms of pricing is its licensing model. SolidWorks uses a perpetual licensing model, meaning that users can purchase a license for the software outright and use it indefinitely. Siemens NX, on the other hand, is only available on a subscription basis, which can make it more expensive in the long run.

Winner

After comparing the features and pricing of Siemens NX and SolidWorks, it’s clear that both software packages have their strengths and weaknesses. So, which one is the winner? The answer to this question depends on the specific needs and preferences of the user. If advanced simulation capabilities and support for a wide range of manufacturing processes are important, then Siemens NX is the clear winner. Its powerful simulation tools and parametric modeling capabilities make it an excellent choice for designers and engineers working on complex projects. On the other hand, if 3D CAD modeling is the primary focus, then SolidWorks is the winner. Its user-friendly interface and range of advanced features, including parametric modeling and assembly modeling, make it a popular choice among mechanical engineers. When it comes to pricing, SolidWorks is generally more affordable than Siemens NX, with a range of different editions available to suit different needs and budgets. SolidWorks also uses a perpetual licensing model, which can be more cost-effective in the long run for users who plan to use the software for an extended period. Ultimately, the choice between Siemens NX and SolidWorks will depend on the specific needs and budget of the user. Both software packages are powerful and versatile and offer a range of features and tools to help designers and engineers bring their ideas to life. The key is to evaluate the strengths and weaknesses of each package and choose the one that best fits the user’s unique requirements.

Conclusion

Siemens NX and SolidWorks are both powerful and versatile CAD/CAM/CAE software packages with their strengths and weaknesses. While Siemens NX offers advanced simulation capabilities and support for a wide range of manufacturing processes, it is also more expensive than SolidWorks. SolidWorks on the other hand is more focused on 3D CAD modeling and is available at a lower price point. Ultimately, the choice between these two software packages will depend on the specific needs and budget of the user.

Summary

Siemens NX and SolidWorks are two of the most widely used software packages in the world of computer-aided design (CAD), computer-aided manufacturing (CAM), and computer-aided engineering (CAE). Both software packages offer a comprehensive set of features and tools that are designed to help designers and engineers create complex parts and assemblies, and analyze their performance under various conditions.

One of the key features of Siemens NX is its advanced simulation capabilities. This software package offers a range of simulation tools that are designed to help users analyze the performance of their parts and assemblies under different conditions, such as stress, vibration, and thermal analysis. Additionally, Siemens NX also supports a range of manufacturing processes, including milling, turning, and sheet metal fabrication.

SolidWorks, on the other hand, is primarily focused on 3D CAD modeling. This software package is known for its user-friendly interface and range of advanced features, including parametric modeling and assembly modeling. Additionally, SolidWorks also offers simulation and analysis tools, although they are more limited in scope than the tools available in Siemens NX.

When it comes to pricing, Siemens NX is generally more expensive than SolidWorks. However, Siemens NX also offers more advanced features and capabilities, which may justify the higher cost for some users. SolidWorks, on the other hand is available in a range of different editions, including a free version for personal use, which makes it a more affordable option for users who don’t require the advanced features available in Siemens NX.

Ultimately, the choice between Siemens NX and SolidWorks will depend on the specific needs and preferences of the user. Both software packages have their strengths and weaknesses, and it’s important to evaluate these factors carefully before making a decision. Whether you’re a designer or an engineer, choosing the right CAD/CAM/CAE software can help you bring your ideas to life more effectively and efficiently.