Short Verdict

In this article, we have a comparison of two powerful CAD software ( Autodesk Inventor vs Fusion 360 ) Inventor and Fusion 360 are both powerful 3D design and engineering software tools developed by Autodesk. Both programs offer a range of advanced features that enable designers and engineers to create complex designs, visualize their creations, and simulate real-world performance.

Inventor is primarily geared towards mechanical design and engineering. It provides a comprehensive set of tools for creating 3D models, assemblies, and drawings. It has a more traditional interface that is easy to use and navigate. Inventor is well-suited for creating models of parts and products that have moving components and require precise tolerances.

On the other hand, Fusion 360 is a more comprehensive design tool that includes features for mechanical design, electronics design, and industrial design. Fusion 360 has a modern interface and offers cloud-based collaboration, which makes it easy to work on projects with a team. Fusion 360 also includes CAM (computer-aided manufacturing) capabilities, which allow designers to create tool paths for CNC machines and 3D

What is an Inventor?

Inventor is a professional-grade 3D modeling software program designed for product designers, engineers, and manufacturers. It is a powerful tool that offers advanced features such as parametric modeling, assembly design, sheet metal design, and simulation. Inventor allows users to create complex 3D models and assemblies with thousands of parts. It is ideal for large businesses that require robust features for designing and manufacturing products Inventor is a professional-grade 3D modeling software program designed for professionals.

What is Fusion 360?

Fusion 360 is a cloud-based 3D modeling software program designed for small and medium-sized businesses and startups. It offers a range of features such as parametric modeling, sheet metal design, and simulation, as well as cloud-based collaboration tools that allow multiple users to work on the same project simultaneously. Fusion 360 also offers advanced manufacturing capabilities such as CNC machining, 3D printing, and CAM (computer-aided manufacturing) integration.

Advantages and Disadvantages of Inventor and Fusion 360

Advantages of Inventor

- Robust design tools: Inventor has a vast array of powerful design tools, including 3D modeling, assembly design, and simulation capabilities.

- Large user community: Inventor has a large and active user community, which means there is a wealth of online resources and support available to users.

- Integration with other Autodesk products: If you use other Autodesk products, such as AutoCAD Inventor integrates seamlessly with them.

- Good for large-scale projects: Inventor is well-suited to large-scale engineering projects, making it a popular choice for aerospace and automotive design.

Disadvantages of Inventor

- Steep learning curve: Inventor can be complex and difficult to learn, particularly for beginners.

- Expensive: Inventor is premium CAD software, and its licensing fees can be prohibitively expensive for smaller businesses or individual users.

- Limited cloud-based collaboration: While Inventor does offer some cloud-based collaboration features, they are not as robust as those offered by other CAD programs like Fusion 360.

Advantages of Fusion 360

- Ease of use: Fusion 360 has a more user-friendly interface and is generally easier to learn and use than Inventor.

- Affordable: Fusion 360 is much more affordable than Inventor, with several pricing plans available to suit different budgets.

- Cloud-based collaboration: Fusion 360 has robust cloud-based collaboration features, making it easy for teams to work together on projects from anywhere.

- Good for smaller projects: Fusion 360 is well-suited to smaller-scale engineering projects, making it a popular choice for hobbyists and small businesses.

Disadvantages of Fusion 360

- Limited design tools: Fusion 360 has a more limited set of design tools compared to Inventor, which may make it less suitable for large-scale engineering projects.

- Dependence on cloud-based services: Because Fusion 360 is cloud-based users are dependent on stable internet connections to use the software effectively.

- Limited customization: While Fusion 360 is highly customizable, it is not as flexible as Inventor in terms of customizing workflows and interfaces.

How do both these Programs work?

Inventor

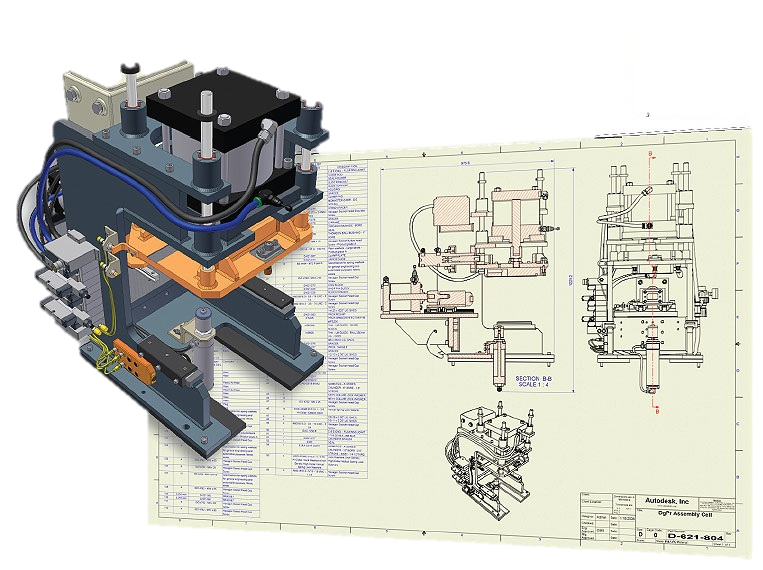

Inventor is professional-grade 3D CAD software that is widely used in industries such as manufacturing, automotive, and aerospace. The software is primarily used for creating and simulating complex mechanical designs, and it has a wide range of advanced tools to support this.

The design process in Inventor starts with sketching 2D profiles of the part or assembly using geometric shapes and constraints. Inventor has a wide range of sketching tools, including lines, arcs, circles, and many more. The software also allows you to add geometric constraints to ensure that the sketch is fully defined and to ensure that it remains stable even when changes are made.

Once the sketch is complete, you can extrude it into a 3D model by specifying the thickness and height of the part. Inventor also has a wide range of tools for modifying the 3D model, including fillets, chamfers, patterns, and many more. These tools allow you to refine the design and make it more functional. One of the key features of Inventor is parametric modeling. This means that changes made to the model are automatically propagated to all dependent features. For example, if you change the diameter of a hole, the software will automatically update any related features, such as fillets or chamfers, to ensure that the model remains stable and functional.

Inventor also allows for the assembly of multiple parts into a single assembly. This can be done by creating a new assembly file and inserting the individual part files. The software has a wide range of tools for assembling parts, including constraints, joints, and connections. These tools allow you to simulate the motion of parts and assemblies, and to identify any design flaws or performance issues. Inventor also has tools for simulating the motion of parts and assemblies. These simulations can help identify design flaws and optimize performance. The software has a wide range of simulation tools, including static stress analysis, linear and nonlinear dynamics, thermal analysis, and many more. These tools allow you to test the design under various conditions and make any necessary adjustments to optimize performance.

Overall, Inventor is powerful 3D CAD software that is ideal for mechanical engineers and product designers who need to create and simulate complex mechanical designs.

Fusion 360

Fusion 360 is a cloud-based 3D modeling software developed by Autodesk. The software is designed for product designers, engineers, and manufacturers who need a comprehensive tool for designing, simulating, and visualizing their products. Fusion 360 offers a wide range of features, including 3D modeling, simulation, visualization, and computer-aided manufacturing (CAM).

Fusion 360 works by providing a user-friendly interface that allows designers to create 3D models using various tools and techniques. The software supports a wide range of file formats, which makes it easy to import and export design files. Fusion 360 also provides simulation tools that allow designers to test their designs for strength, durability, and performance. The simulation tools can help designers identify and address any design flaws before the product is manufactured.

Fusion 360 also offers computer-aided manufacturing (CAM) capabilities, which allows for a seamless transition from design to production. The software supports a wide range of manufacturing processes, including milling, turning, laser cutting, and 3D printing. Fusion 360’s CAM tools can generate tool paths and machine code directly from the 3D model, which can save time and reduce errors.

Fusion 360 is cloud-based software, which means that it is dependent on an internet connection. This can be a problem for users who have a slow or unreliable internet connection. Fusion 360 also has a steep learning curve, which may require significant time and effort to master. While Fusion 360 offers a wide range of features, some advanced users may find its functionality limited compared to more specialized design tools. In addition, as Fusion 360 is a cloud-based tool, there may be security concerns regarding the storage and sharing of design files.

In conclusion, Inverter and Fusion 360 are two very different technologies with different applications. Inverter technology is used to

Comparing the Features of Inventor and Fusion 360

Now, let’s compare the key features of Inventor and Fusion 360 to determine which one is better:

Parametric Modeling

Both Inventor and Fusion 360 offer parametric modeling, which allows users to create 3D models with intelligent constraints and relationships. However, Inventor has more advanced parametric modeling features than Fusion 360.

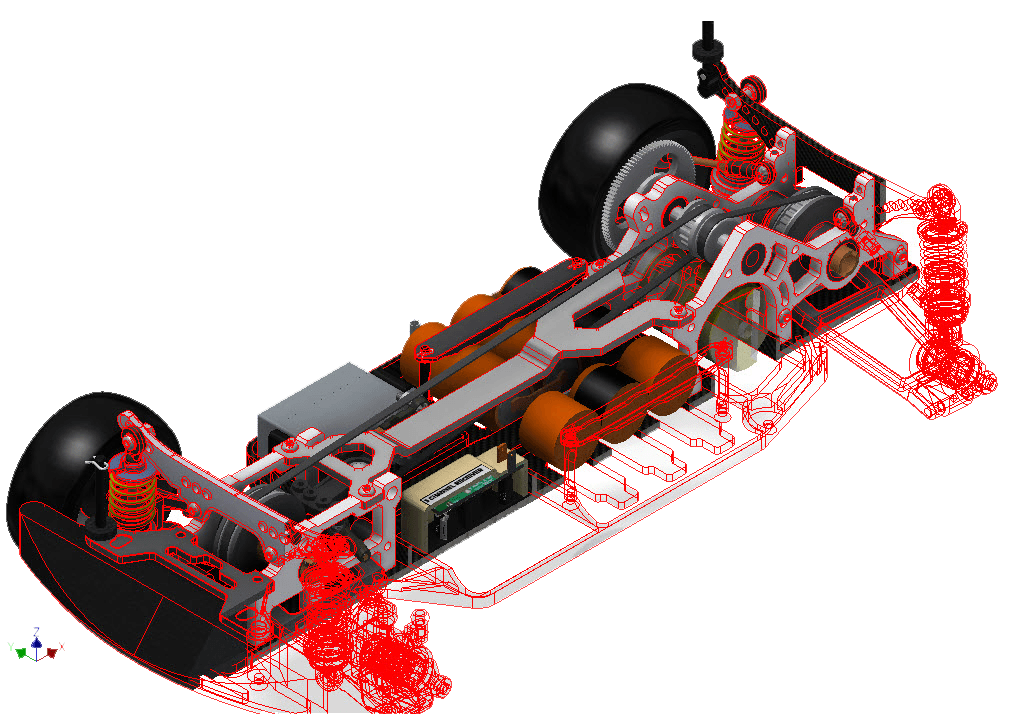

Assembly Design

Inventor is known for its powerful assembly design capabilities, which allow users to create complex assemblies with hundreds or even thousands of parts. Fusion 360 also offers assembly design features, but they are not as robust as those in Inventor.

Sheet Metal Design

Inventor offers advanced sheet metal design features that allow users to create sheet metal parts and assemblies. Fusion 360 also offers a sheet metal design, but the functionality is not as extensive as in Inventor.

Cloud-Based Collaboration

Fusion 360 is designed for cloud-based collaboration and offers advanced collaboration tools that allow multiple users to work on the same project simultaneously. Inventor does not offer cloud-based collaboration and is designed for individual use or small teams.

Price

This criterion compares the pricing structure of Inventor and Fusion360. According to the Autodesk website as of February 2023, Inventor is priced at $2,315 per year, while Fusion360 has several pricing options including a free personal use plan and a commercial use plan starting at $495 per year. Based on these prices, Fusion360 is the winner for this criterion.

User Experience

This criterion evaluates the overall ease of use and user interface of Inventor and Fusion360, with a time declared if the software has comparable user experiences.

Learning Curve

This criterion assesses the difficulty or ease of learning and mastering Inventor and Fusion360, with a tie declared if the software has similar learning curves.

Capabilities

This criterion examines the range and depth of features and tools offered by Inventor and Fusion360. Based on user reviews and industry evaluations, Inventor is the winner for this criterion.

Parts Library

This criterion looks at the availability and quality of pre-built parts and components that can be used in Inventor and Fusion360. Based on user reviews and industry evaluations, Inventor is the winner for this criterion.

Assemblies

This criterion evaluates the ability of Inventor and Fusion360 to handle complex assemblies and large-scale designs. Based on user reviews and industry evaluations, Inventor is the winner for this criterion.

Materials

This criterion assesses the range and variety of materials that can be used in Inventor and Fusion360. Based on user reviews and industry evaluations, Inventor is the winner.

Simulation

This criterion examines the ability of Inventor and Fusion360 to simulate real-world conditions and test designs before prototyping. Based on user reviews and industry evaluations, Inventor is the winner for this criterion.

CAM

This criterion evaluates the ability of Inventor and Fusion360 to generate tool paths and machine code for CNC machining. Based on user reviews and industry evaluations, Inventor is the winner for this criterion.

Winner: Fusion 360

After comparing the key features of Inventor and Fusion 360, we have determined that Fusion 360 is the winner. While Inventor offers advanced features such as robust assembly design and simulation capabilities, it is more expensive and is designed for larger businesses. Fusion 360 offers similar features at a more affordable price point and is designed for small and medium-sized businesses and startups. It also offers cloud-based collaboration tools that allow multiple users to work on the same project simultaneously, which is a valuable feature in today’s remote work environment.

Conclusion

Inventor and Fusion 360 are both powerful 3D modeling software programs that offer a range of advanced features for creating

Summary

In summary, Inventor and Fusion 360 are both powerful 3D CAD software used for designing and simulating complex mechanical designs. Inventor is a professional-grade software widely used in industries such as manufacturing, automotive, and aerospace. It is primarily used for creating and simulating complex mechanical designs, and it has a wide range of advanced tools to support this. On the other hand, Fusion 360 is a cloud-based 3D CAD software designed for a broader audience, including mechanical engineers, product designers, architects, and hobbyists. It offers a more integrated workflow, including tools for parametric modeling, generative design, simulation, rendering, and CAM.

Both Inventor and Fusion 360 use a similar approach to create 3D models of parts and assemblies. The design process in Inventor starts with sketching 2D profiles of the part or assembly using geometric shapes and constraints, while Fusion 360 has a wide range of modeling tools, including sketching, direct modeling, sculpting, and parametric modeling. Both software allows for the assembly of multiple parts into a single assembly, and both offer simulation tools to test the design under various conditions and optimize performance.

Overall, Inventor is ideal for mechanical engineers and product designers who need to create and simulate complex mechanical designs, while Fusion 360 is suitable for a broader audience, including hobbyists and architects. Both software has their strengths and weaknesses, and choosing the right one depends on the specific needs and requirements of the user.